- HOME

- PRODUCTS

- NEWS

- ABOUT US

- Download

- CONTACT US

| Availability: | |

|---|---|

| Quantity: | |

4050

Remax

Parameter

| Description | Parameter of cnc milling machine |

| X,Y,Z Working Area | 400*500*300mm |

| X,Y,Z Repositioning Accuracy | 0.02mm |

| Table Surface | T-slot Table |

| Frame | Whole machine cast by iron |

| X, Y,Z Structure | 25mm Hiwin Square Rail and TBI Ball Screw |

| Motor and driver | Japan Yaskawa servo motor and driver |

| Spindle Power | 5.5kw water cooling spindle |

| Spindle Speed | 0-24000RPM |

| Working Voltage | AC220/380V 50/60Hz |

| Command Language | G Code |

| Inverter | Fuling |

| Electrical components | Schneider |

| Limit switch | OMRON |

| Running Environment Temperature | 0-45 Centigrade |

| Relative Humidity | 30%-75% |

Features

2. Stable and rigid structure: The gantry bed and the bed are integrated, the machine has good rigidity, and both have no installation errors. So even if it is used for a long time, the processing accuracy will not be affected.

3. CNC moulding machine is a fully enclosed design and adopts an external circulating cutting oil processing method. The body is fully cast, with stable structure and strong bearing capacity.

4. The whole machine is equipped with a well-known brand of precision bidirectional ball screw, Taiwan square rails and precision bearings with strong rigidity and high dynamic precision.

Machine parts

Machine sample

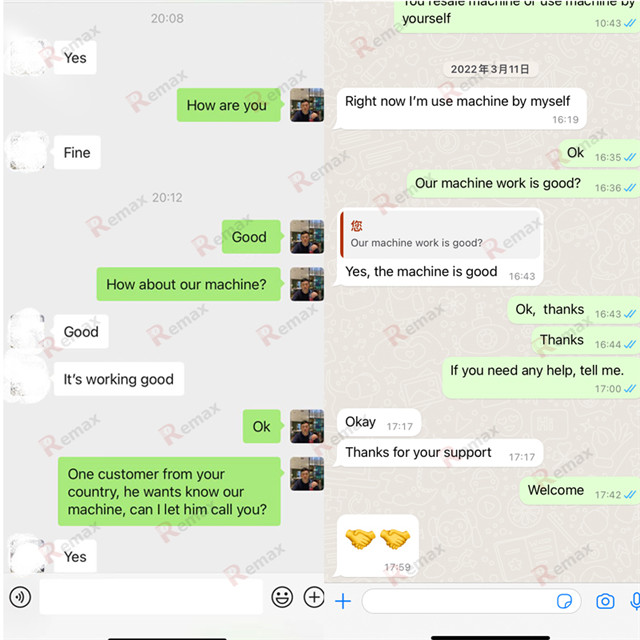

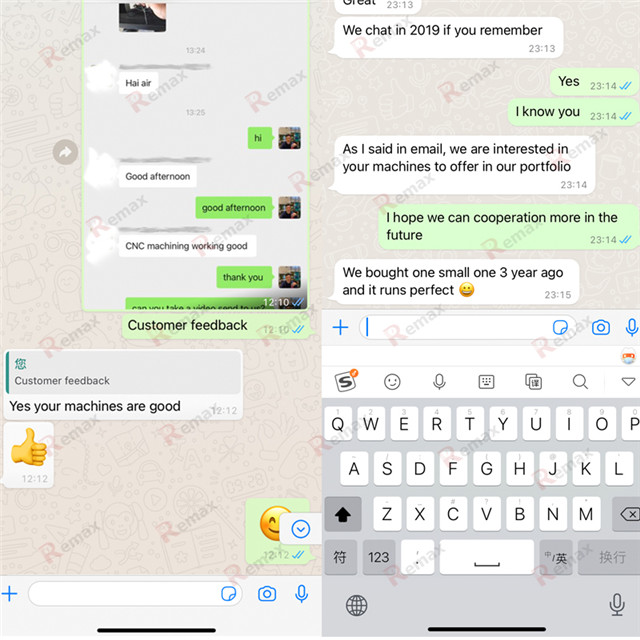

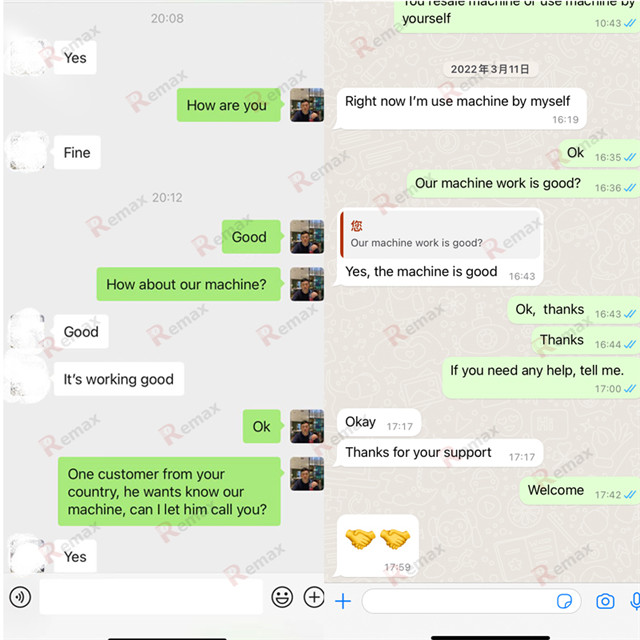

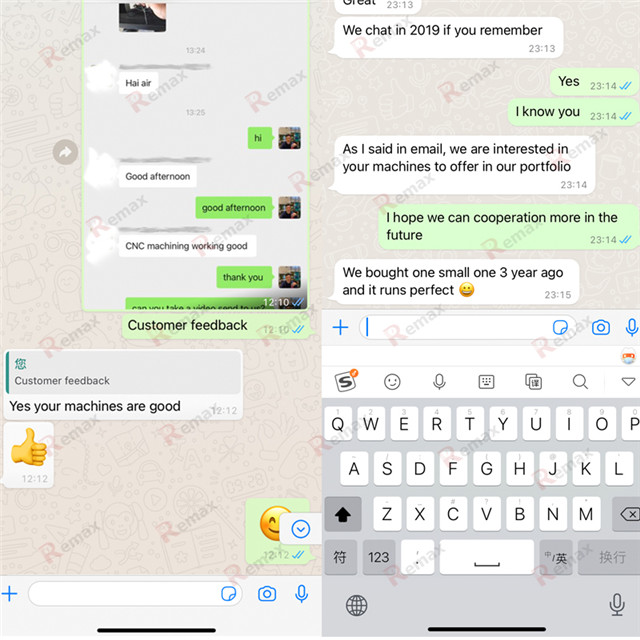

5 Customer feedback

6 Company Profile

7 FAQ

Q:I got the Artcam software to work. I actually use another design program Fusion 360 or sketchup.

A:Ok, For the Artcam software sent to you, because some customers don`t have drawing software themselves,we give it for free.If you have drawing software, you can also use it, as long as the drawing software can generate G code.

Q:What is the correct procedure to get my files to operate on the CNC?

A:After you finish the drawing in the software, generate G code, export it to the U disk, then insert the U disk into the handle,find and open the file in the handle to operate the machine.

Q:I don't how to use machine.

A:Don't worry friend, we will send you the English manual and teaching video, you can learn from it, if you still have problem, our engineer can video teach you or go to your country training you.

Q: For the water cooling spindle and air cooling spindle, I don’t know how to choose it.

A: For the 2 spindles, if you mainly process metal and stone, choose water cooling spindle is best; you mainly process wood, acrylic etc non-metal materials, choose air cooling spindle is better.

Q:Can you make sample for me? I want to see how the machine works.

A: Yes we can, you send sample picture or provide STL format files to us is ok.

Q: What kind of tools can I choose? Can I buy more from you.

A: We will provide one box tools for you with the machine. If you want more, you can buy from us.

Q: How to connect the machine to the computer?

A: Different control systems have different connection methods, we will guide you and provide manual.

8 Our service

A Guarantee:

12 months for the whole machine.

Within 12 months under normal use and maintenance,

if machine parts have problem, you will get spare part for free, we pay for shipping cost.

Out of 12 months, you will get spare part at cost price.

You will also get technical support and service all the lifetime.

B Technical support:

1, Technical support by phone, email or MSN/Skype 24 HOURS

2, Friendly English version manual and operation video CD disk

3, Engineer available to service machinery overseas

C After sales services:

Normal machine is properly adjusted before dispatch.

You will be able to use the machines immediately.

You will be able to get free training advice towards our machine in our factory.

You will also get free suggestion and consulting, technical support and service by

email/fax/tel and lifetime technical support.

Parameter

| Description | Parameter of cnc milling machine |

| X,Y,Z Working Area | 400*500*300mm |

| X,Y,Z Repositioning Accuracy | 0.02mm |

| Table Surface | T-slot Table |

| Frame | Whole machine cast by iron |

| X, Y,Z Structure | 25mm Hiwin Square Rail and TBI Ball Screw |

| Motor and driver | Japan Yaskawa servo motor and driver |

| Spindle Power | 5.5kw water cooling spindle |

| Spindle Speed | 0-24000RPM |

| Working Voltage | AC220/380V 50/60Hz |

| Command Language | G Code |

| Inverter | Fuling |

| Electrical components | Schneider |

| Limit switch | OMRON |

| Running Environment Temperature | 0-45 Centigrade |

| Relative Humidity | 30%-75% |

Features

2. Stable and rigid structure: The gantry bed and the bed are integrated, the machine has good rigidity, and both have no installation errors. So even if it is used for a long time, the processing accuracy will not be affected.

3. CNC moulding machine is a fully enclosed design and adopts an external circulating cutting oil processing method. The body is fully cast, with stable structure and strong bearing capacity.

4. The whole machine is equipped with a well-known brand of precision bidirectional ball screw, Taiwan square rails and precision bearings with strong rigidity and high dynamic precision.

Machine parts

Machine sample

5 Customer feedback

6 Company Profile

7 FAQ

Q:I got the Artcam software to work. I actually use another design program Fusion 360 or sketchup.

A:Ok, For the Artcam software sent to you, because some customers don`t have drawing software themselves,we give it for free.If you have drawing software, you can also use it, as long as the drawing software can generate G code.

Q:What is the correct procedure to get my files to operate on the CNC?

A:After you finish the drawing in the software, generate G code, export it to the U disk, then insert the U disk into the handle,find and open the file in the handle to operate the machine.

Q:I don't how to use machine.

A:Don't worry friend, we will send you the English manual and teaching video, you can learn from it, if you still have problem, our engineer can video teach you or go to your country training you.

Q: For the water cooling spindle and air cooling spindle, I don’t know how to choose it.

A: For the 2 spindles, if you mainly process metal and stone, choose water cooling spindle is best; you mainly process wood, acrylic etc non-metal materials, choose air cooling spindle is better.

Q:Can you make sample for me? I want to see how the machine works.

A: Yes we can, you send sample picture or provide STL format files to us is ok.

Q: What kind of tools can I choose? Can I buy more from you.

A: We will provide one box tools for you with the machine. If you want more, you can buy from us.

Q: How to connect the machine to the computer?

A: Different control systems have different connection methods, we will guide you and provide manual.

8 Our service

A Guarantee:

12 months for the whole machine.

Within 12 months under normal use and maintenance,

if machine parts have problem, you will get spare part for free, we pay for shipping cost.

Out of 12 months, you will get spare part at cost price.

You will also get technical support and service all the lifetime.

B Technical support:

1, Technical support by phone, email or MSN/Skype 24 HOURS

2, Friendly English version manual and operation video CD disk

3, Engineer available to service machinery overseas

C After sales services:

Normal machine is properly adjusted before dispatch.

You will be able to use the machines immediately.

You will be able to get free training advice towards our machine in our factory.

You will also get free suggestion and consulting, technical support and service by

email/fax/tel and lifetime technical support.